![]()

NOTE:Click on picture to enlarge. Click back button on your browser to return to this page.

|

About 40 years ago. I purchased an Athearn Cow/Calf combination along with a Hobbytown of

Boston Yard Switcher power chassis kit #45408F. I modified it with spark arrestor exhaust stacks.

The stairs on the cabless unit were boxed in just like on the real engine. Added handrails on the

chassis instead of on the hoods and my NY,V, & N Rwy color scheme. I had always wanted a "herd".

In other words two cabless engines and one with a cab. I had first seen pictures of these in Jerry

Pinkepanke's Second Diesel Spotters Guide. I scored a second yard switcher kit on e-bay recently

with a metal Cary Alco S2/S4 metal shell. Not wanting the Cary shell to be without a chassis I scored

another switcher chassis on E-bay. Now I have my "herd". Right picture above.

I searched the net for pictures of C&O's herd and came across two pictures. There were only two

sets built. Both for the C&O.

Here's a link to good information on the units:EMD TR3 Cow/Calf/Calf

|

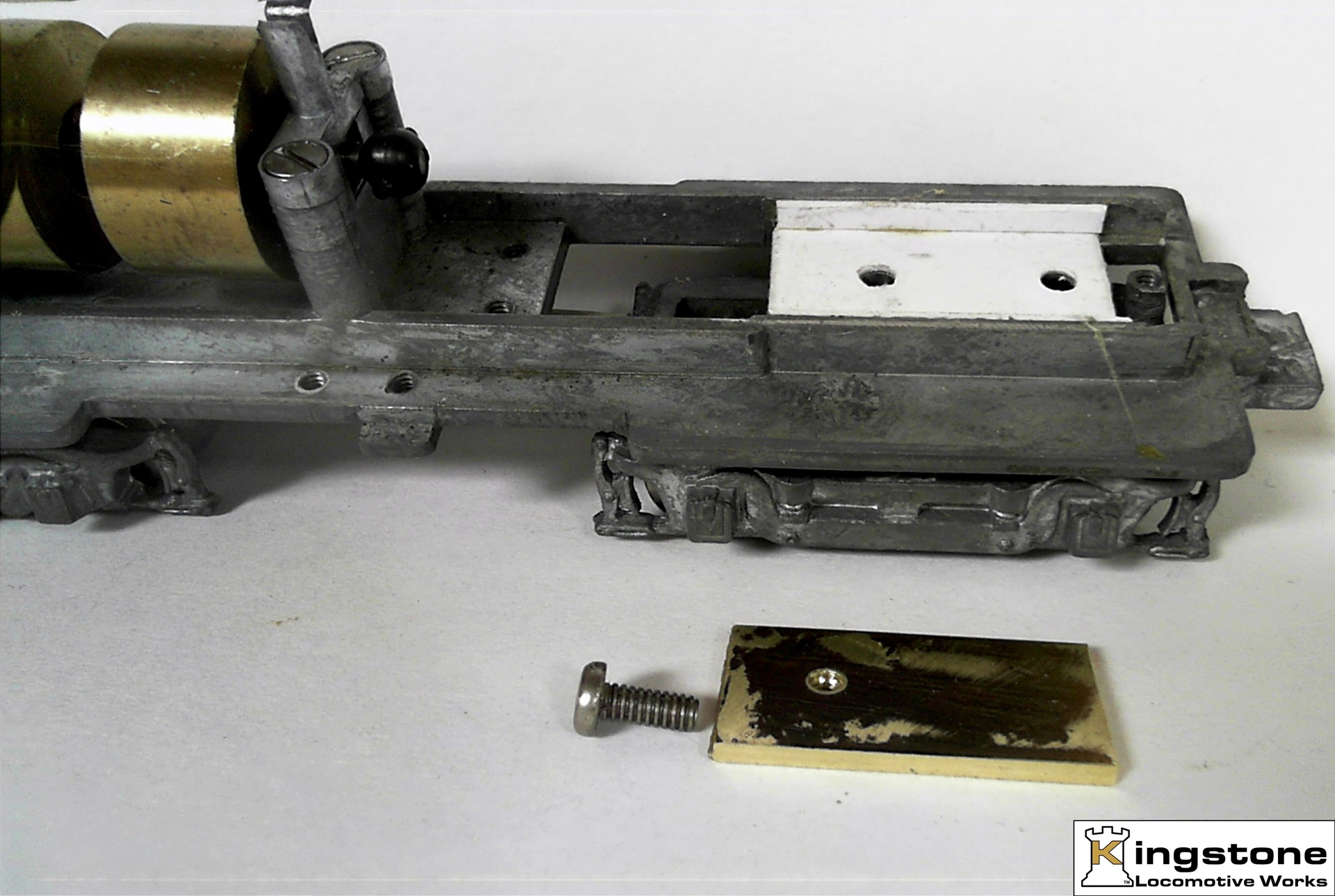

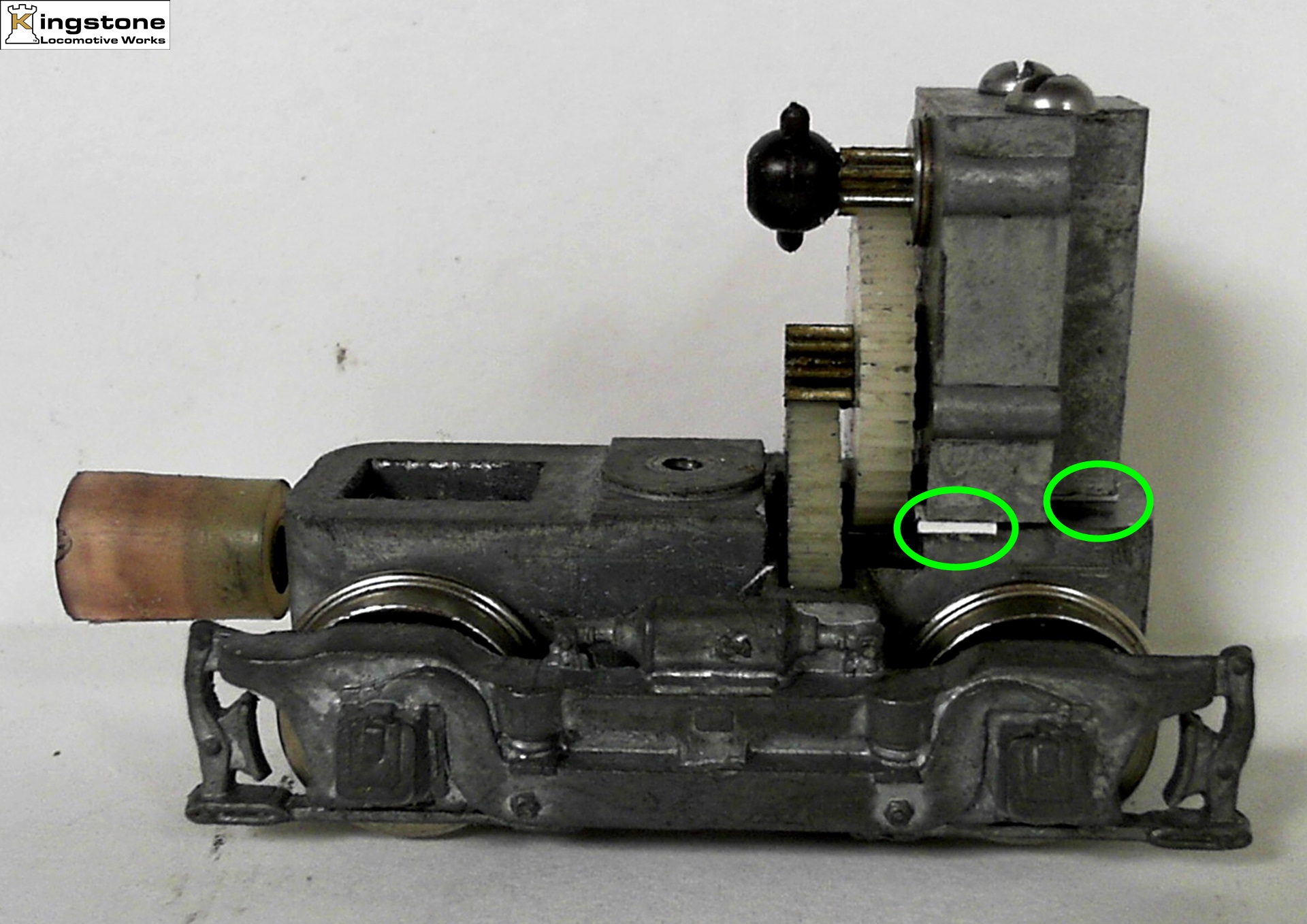

Here's a closer look at the new acquisition with the Mashima can motor that will be used. Note the misalignment at the gear tower. Another item that needs modifying. |

|

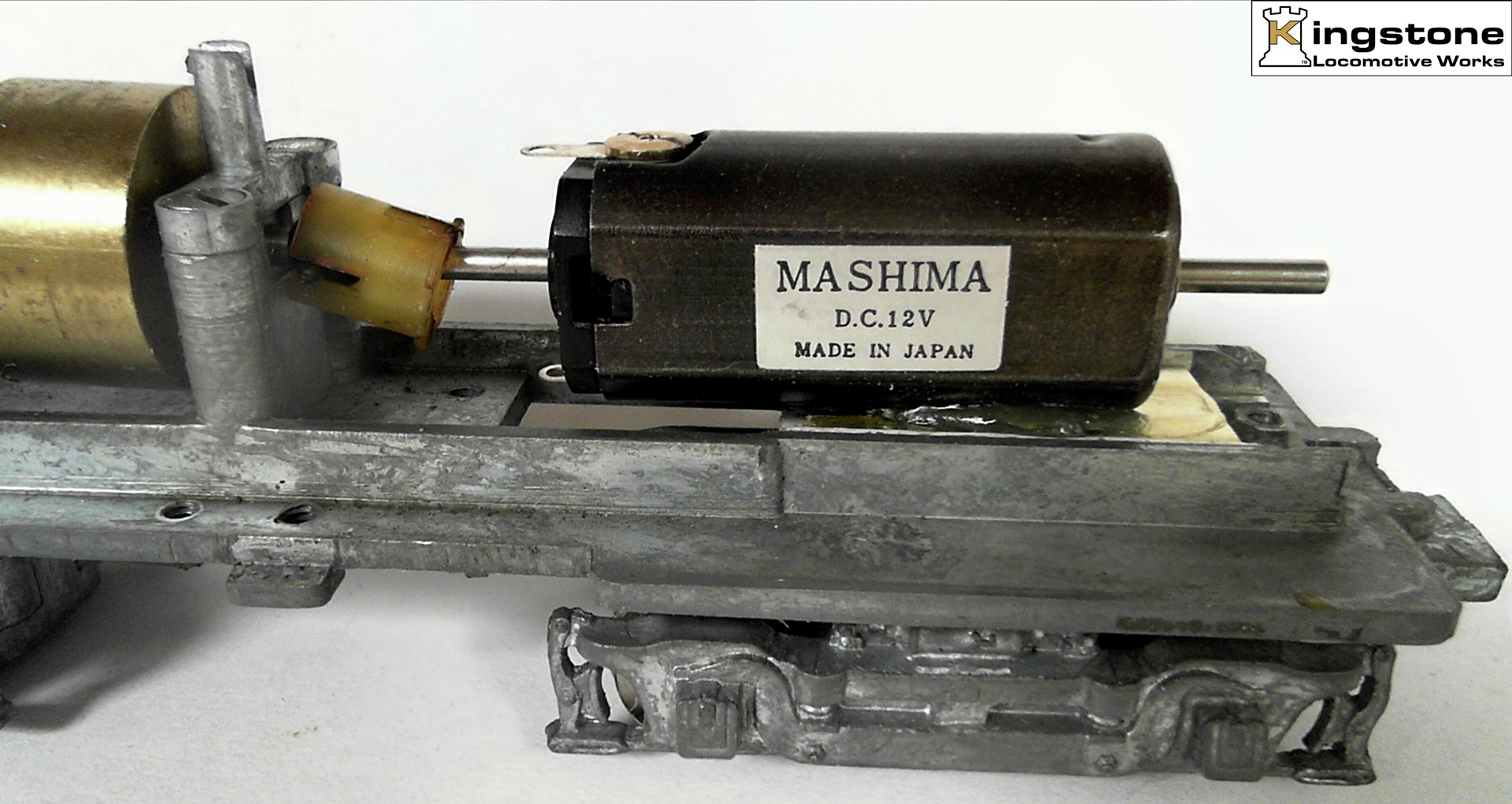

I glued in some styrene with Pliobond for insulation of the motor. The brass strip is for mounting the truck. Note screw hole. |

|

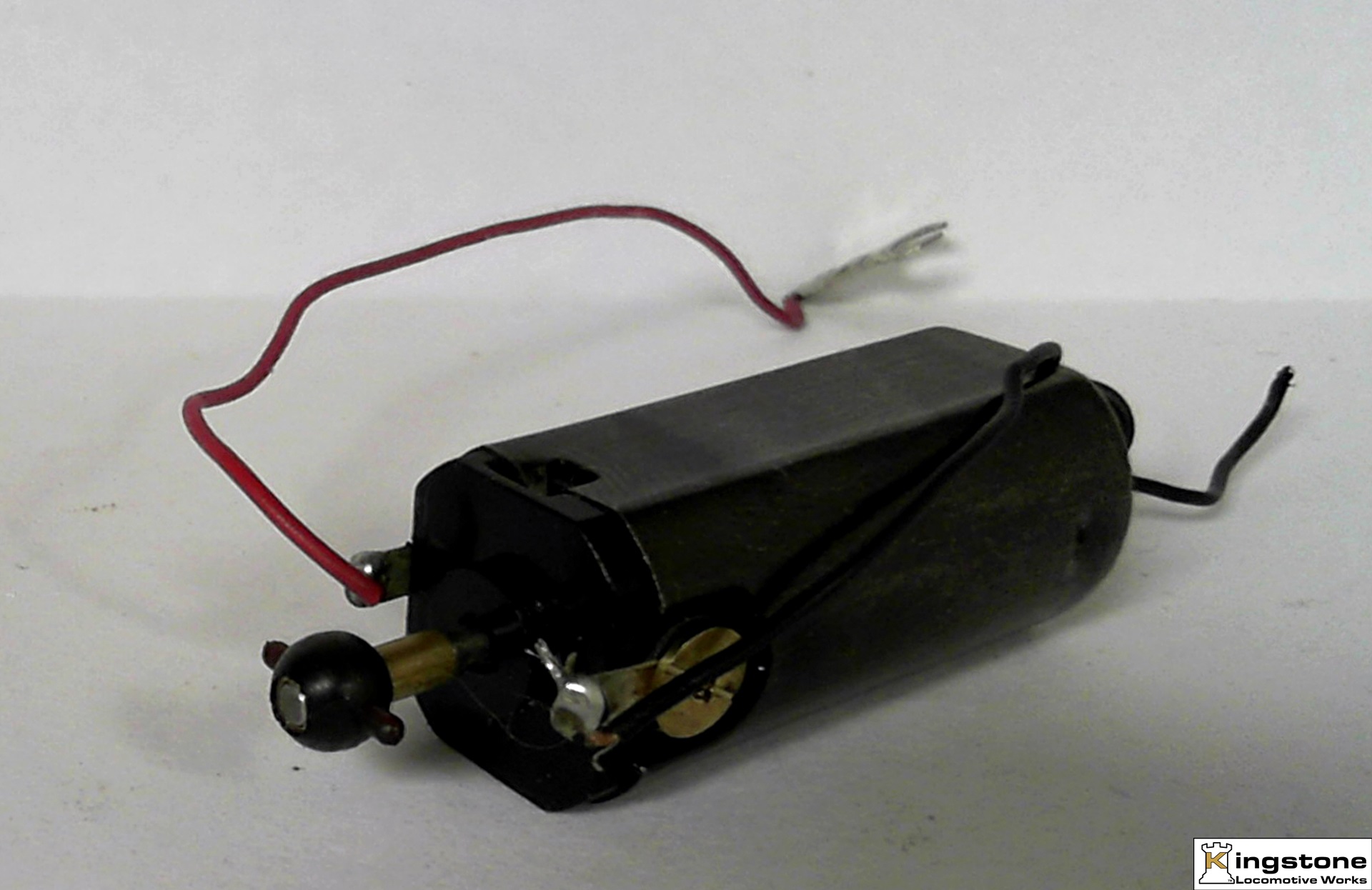

I mounted the motor in a dab of clear silicone caulking just to see how the motor would proform on this drive. |

|

Loctite© was used to hold the bushing on the motor shaft. The U-joint ball was a snug fit on the OD of the brass bushing. |

|

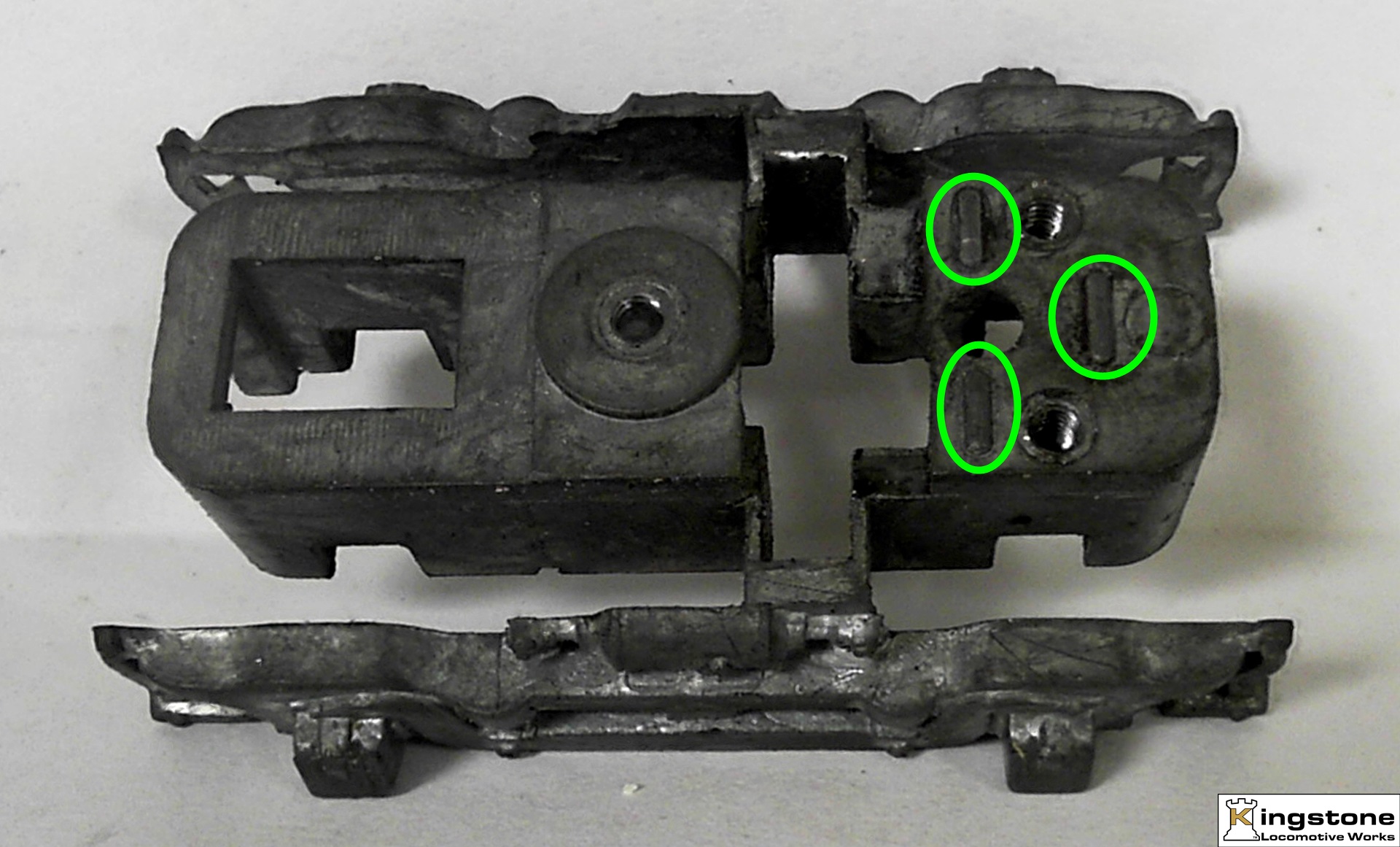

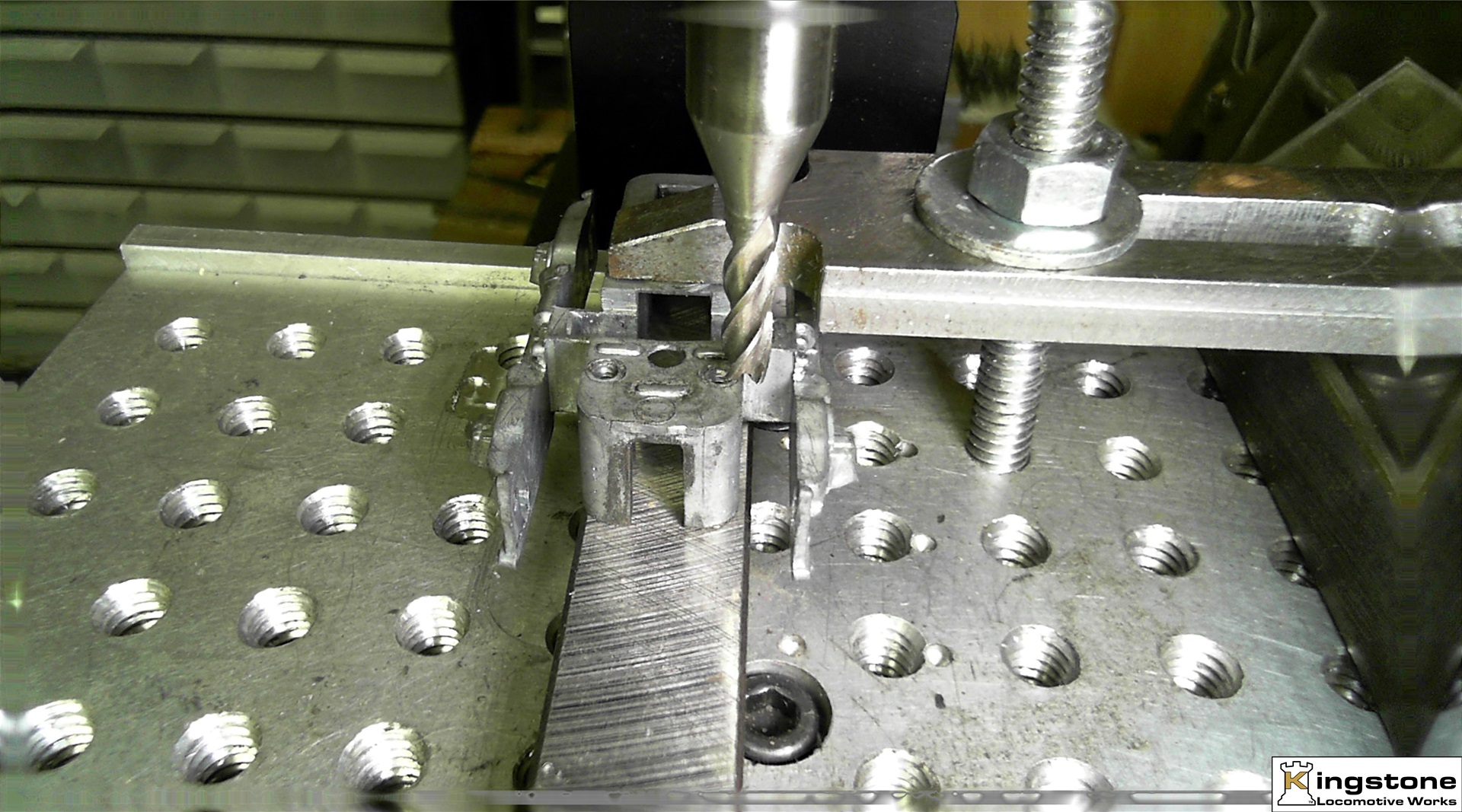

Next the geartower needed some modifacation were it sits on top of the truck. The cast in protrusions needed to be milled off. They are used to ajust the gear lash of the final drive gear. |

|

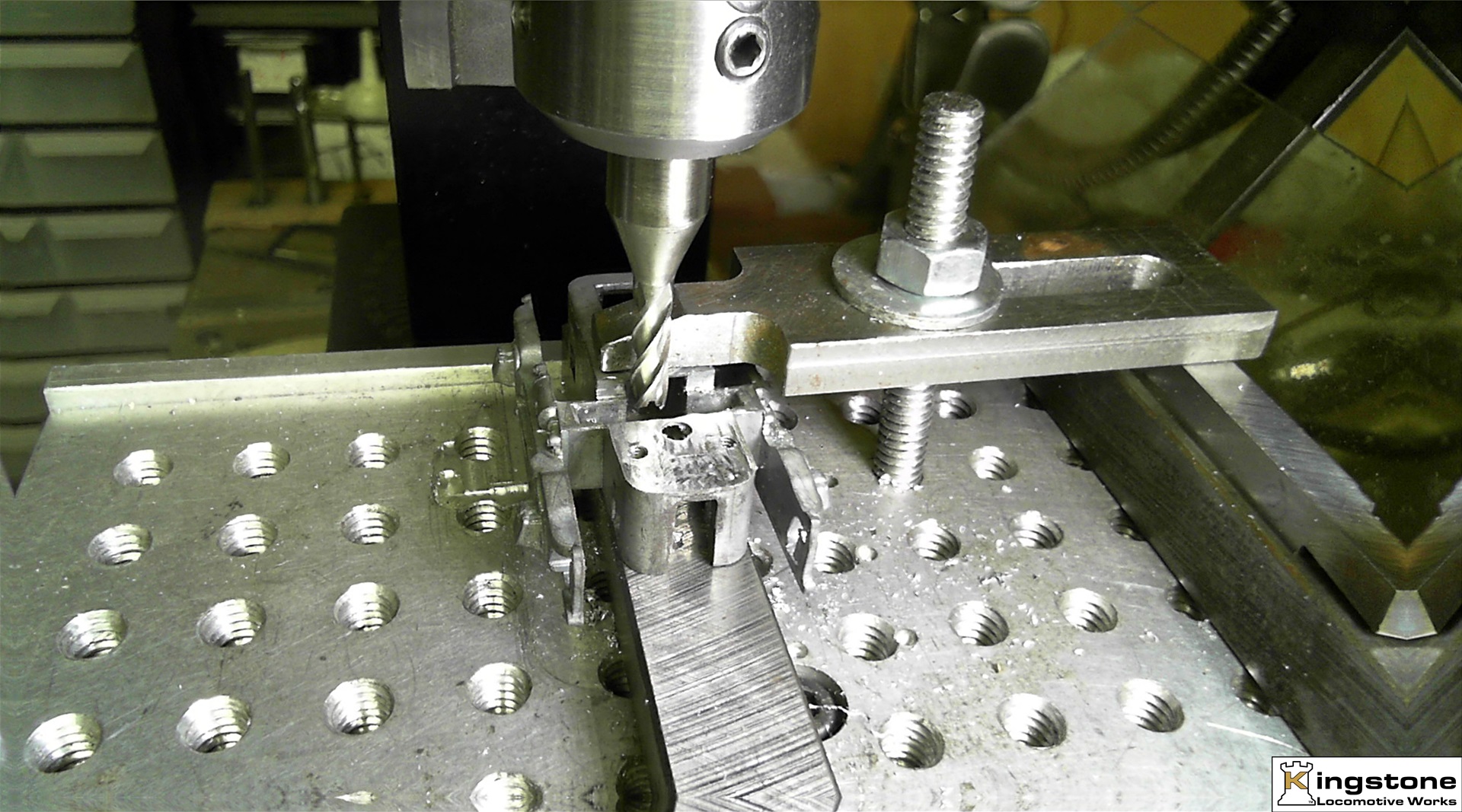

The Sherline Mill was set up to mill the protrusions off nice and flush. |

|

Finished milled. |

|

.020" thick styrene was used to shim the gear for proper backlash. I might change this to brass at a later date. |

This project was started in July 2015. It's a summer project for something to do durning a rainy

day. So

progress will be slow. Also this project is competing with other model railroad projects for a time slot.

Check the

"What's New" page to see what's been done on projects.