![]()

This segment will cover the mechanical rebuild, improvement for electrical pickup, and installation of a Lens non-sound decoder

on a Mantua

0-4-0 steam engine. This is not my model. It belongs to a modeling friends' son. It is his first engine he bought with his own money.

His father

and him were in the process of trying to make it run better. When his father saw some of my work that I've posted here on , he asked if I

could

help in improving the running characteristics of this engine. He and his son installed a can motor but to no avail. It still ran erratically down

the track. At their wits end he asked for my help and I said, "Ya why not."

![]()

|

A picture of the engine sent to me. |

< |

|

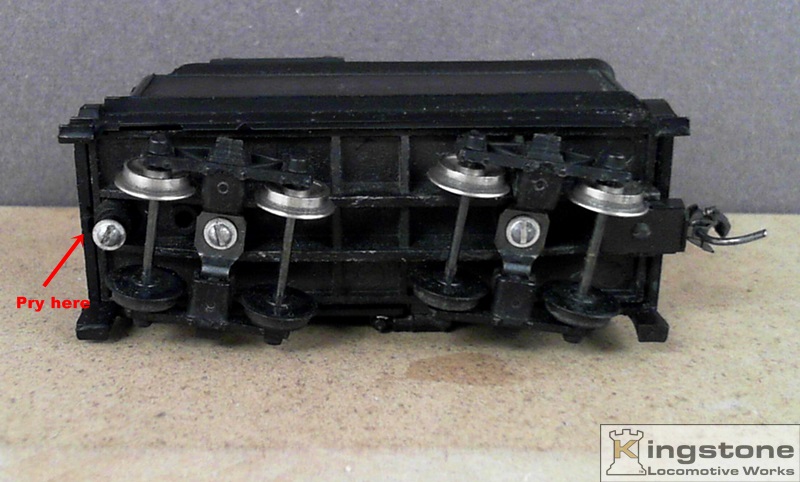

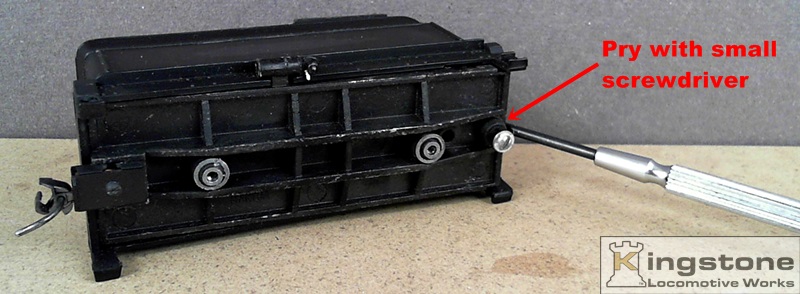

In order to work on the chassis, I needed to remove the plastic shell from the metal chassis. There is a tab by

the |

|

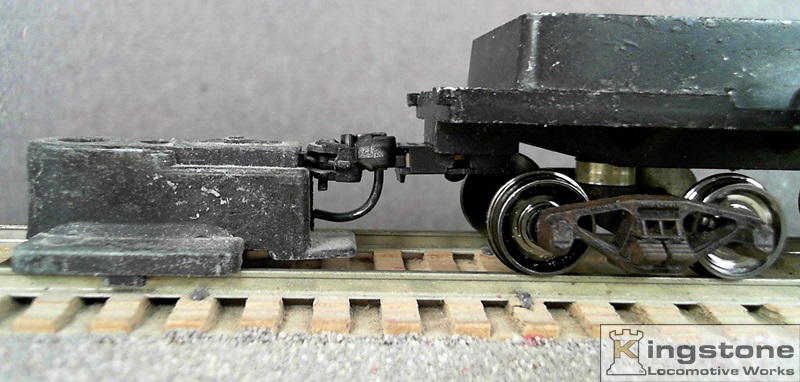

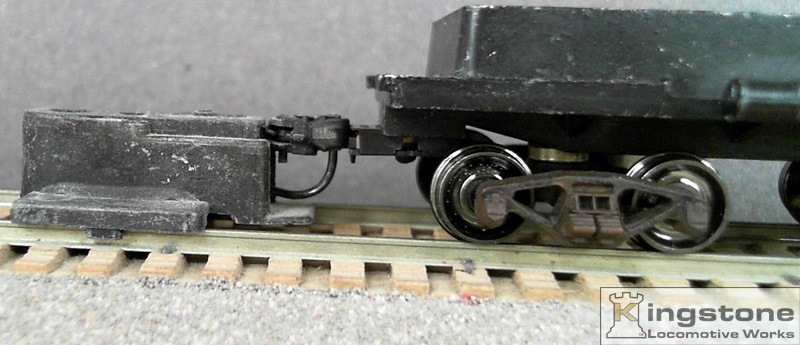

Once I got the shell removed, I tried out the new trucks. It was mentioned that the coupler was a bit low. |

|

There's a lot of info in this picture. The new trucks cannot be screwed on with the screws that hold the

Mantua affiliation, just a satisfied customer. Also, it's not my only source. |

|

Next, I set up my mill and milled out the truck mounting holes in the tender. I went down approximately .250". |

|

|

The bushings are ready for a test fit. |

|

A check with the coupler height gage showed that the bushing's needed to |

|

A coupled of careful trim cuts and the correct height was attained. |